Aluminum Alloy PIR Insulated Great Wall Panel Rolling Forming Machine

Aluminum alloy PIR insulated Great Wall Panel is a kind of exterior siding sandwich panel for our fastest and most low price solution for the en-closre of external wall for industrial buildings, barns, and storage, as well as encasement the walls of buildings, offices or houses, etc. Its main feature is its spectacular aesthetic, since the screw used for its fixation is completely invisible.

It has the following features:

It is crafted with a durable aluminum alloy exterior and a high-performance PU/ PIR core, these panels deliver exceptional heat insulation. Their distinctive linear design, inspired by the iconic Great Wall, provides a visually striking and robust solution for projects demanding both superior aesthetic appeal and structural integrity.

The aluminum great wall panels are ideal for roofs and walls in outdoor pavilions, sun rooms, and canopies, offering effective heat insulation, waterproofing, and sun protection. Take the following drawing profile:

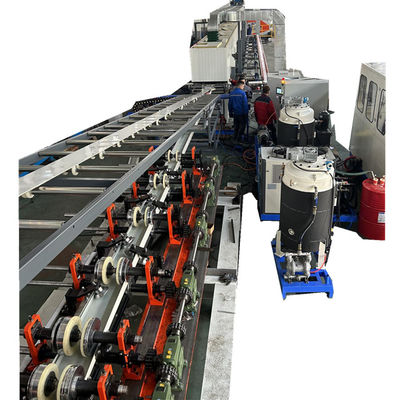

Aluminum Alloy PIR Insulated Great Wall Panel Rolling Forming Machine:

The production line is composed by the following elements:

I. MAIN ROLL FORMER

5-ton hydraulic unwinding machine with 2 sets of trolleys

1250 Great Wall Plate Forming Machine (Upper/Lower Plate) 2 sets

II. Heating device

Hot air heating protection system 1 set

III. High pressure foaming machine

Two component high-pressure foaming machine 1 set

Translation sweeping device 1 set

IV. Double track laminating machine

24M steel chain plate laminating machine 1 set

Screw lifting device 1set

Side block device (one thickness) 1 set

V. Band saw cutting machine

Band saw tracking cutting machine 1set

1 set of fast conveyor belt

1 set of electronic control system

Main technical parameters of the Aluminum Alloy PIR Insulated Great Wall Panel Rolling Forming Machine

Production board specification: Width 1250

Thickness 30mm

Customize length

Panel material: Color steel plate

Core material: hard polyurethane

Density: 40~60kg/m3

Production line speed: 6~8m/min (0~50Hz variable frequency speed regulation)

Double track laminating conveyor length: 24m (effective length 24m)

Hot air circulation maximum temperature: 60 ℃

Dimensions of the production line (length x width x height): approximately 90m (L) x 6m (W) x 6m (H)

Total power: approximately 160kw

◆ Forming panel making machine:

The molding unit consists of two molding machines, namely the front plate and the back plate. Customers can also customize multiple molding units to meet production needs.

Aluminum coil specifications: width 1250mm, thickness 0.3-0.5mm

Molding process: 30 processes

Roller shaft diameter: ø 80

Maximum forming speed: 10m/min

Power: 7.5kw A.C

Variable frequency stepless speed regulation

Pr-heating device

To meet the process requirements, the board needs to be preheated before liquid spraying. Generally, the preheating temperature of the board surface is 25-35 ° C, which is related to the process parameters such as the liquid raw material ratio and foaming speed. It is determined by the wet end requirements. Preheating can be set by heating the surface of the steel plate through a heating tube,

Preheating sets a certain number of electric heating tubes, which can be grouped and controlled separately

Temperature: 50 degrees (adjustable)

Temperature control: digital display self-control

Steel plate temperature: Generally, the preheating temperature of the plate surface is 25-35 ° C, (determined by the wet end requirements)

Heating power: 32kw

Double track laminating conveyor

One upper and one lower crawler conveyor.

Track length: 24m

Track length: 24m

Adjustable foaming width: 900mm

Track chain plate length: 1200mm

Track chain plate width: 220mm

Track chain plate material: 16MN

Track chain plate thickness: total thickness 60mm

Upper track opening height: 200mm

Working face height of lower track: 1200mm

Guide rail material: GCr15, surface hardness HRC58-62 °

Adjustable speed: 3-10m/min

Bearing pressure: 0.6bar/cm2

Conveyor power: 5.5kw × 2, variable frequency stepless speed regulation

Spiral lifting: 24 pieces

Screw diameter Φ 70mm

Automatic tracking and shearing machine

This machine consists of a base, a longitudinal moving mechanism, a cutting machine, and a vacuum cleaner. The longitudinal moving frame is installed on the linear guide rail of the machine base, and is synchronized with the longitudinal movement of the laminating machine through a motor, reducer, and screw drive, and quickly returns to its original position after completing the cutting of the sheet metal.

Now let us check the finished product and overlapping effect:

If you need to know more information, please contact us at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!