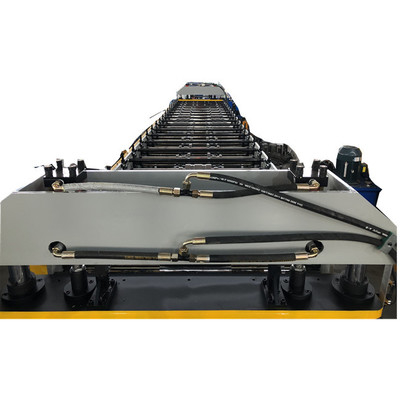

PBR panel rolling machine

A PBR (Purlin Bearing Rib) roof panel roll forming machine is a piece of industrial equipment used in the construction and manufacturing industry. It is designed to automate the process of forming PBR roof panels, which are commonly used in the construction of metal roofs for various buildings, including warehouses, industrial facilities, agricultural structures, and more.

PBR - Panel metal roofs are the long-lasting and beautiful stunning metal roofing option.They are easy to install and this course cuts down on labor,time,and disposal costs.These R panel roofs are available in many different colors.R-Panel/PBR - Panels are very popular for both local and commercial roofing system.

Here is one drawing profile and finished product:

PBR panel rolling machine

Production technology process:

Feeding → Leveling → Forming → hydraulic Cutting after forming → Output

| Machine frame |

350mm H beam structure, with 20mm welded steel middle support plate. |

|

Material of rollers

|

High grade 45# forged steel |

| Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life |

|

Forming stations

|

Upper layer 18 roller station |

| Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. |

| Diameter of shafts |

Φ80mm solid |

| Material of shafts |

High grade 45#,with heat treatment |

| Forming speed |

0-25m/min |

| voltage |

380V/50HZ/3P (as requested) |

| Transmission way |

By 1 inch chain |

| Main motor |

7.5KW |

| Cutting blade material |

Gcr12 quenched treatment |

| Cutting type |

hydraulic post cutting |

| Driving method |

By pillar type Cylinder |

The price of ZTRFM’s roll forming machines is a little higher than other suppliers'. Let me explain about our machines difference:

ZTRFM’s machine design: it is unit one, which means the control box and the hydraulic station are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. it saves more time and space.

Our display screen is touch screen, not text touch screen.

ZTRFM roll forming system: We will make the hand wheels at the feeding device to adjust feeding width, and we also make the wheels with the numbers then you know how to adjust right and left sides, also we made the rulers on the bedding, you can adjust the profile height and width according to the rulers.

Screw with numbers is to adjust material thickness easily, also with protecting cap also add laminating film device and felt to make the board flatter and smoother without scratches.

The machine is equipped with a detection switch device, in case of emergency, emergency alarm, stop operation.

Here's an overview of how PBR panel rolling machine works:

Material Feeding: The machine typically starts with a coil of metal sheet material, often galvanized steel or aluminum. This coil is loaded onto the machine.

Uncoiling: The machine uncoils the metal coil, allowing it to feed continuously into the roll forming process.

Roll Forming: The core function of the machine is roll forming. The metal sheet passes through a series of rollers that gradually shape it into the desired PBR profile. These rollers are custom-designed to produce the specific ribbed pattern characteristic of PBR roof panels. The process involves a series of steps, including pre-cutting, punching holes if necessary, and forming the ribs.

Cutting: After the roll forming process, the continuous metal sheet is cut into individual PBR roof panel lengths. This can be done using various cutting mechanisms, such as hydraulic shears or flying cutoffs, depending on the machine's design.

Stacking or Packaging: Once the panels are cut to the desired length, they are either stacked or packaged for transportation and further processing.

PBR roof panels are known for their high structural integrity due to their ribbed design, making them suitable for withstanding heavy loads and adverse weather conditions. They are also efficient to produce in large quantities using a roll forming machine.

It's worth noting that there are different variations of PBR roof panel roll forming machines available, with varying levels of automation and production capacities. The specific features and capabilities of a machine may vary based on the manufacturer and model. These machines are commonly used in metal roofing and siding manufacturing plants, and they play a crucial role in the construction industry by producing durable and cost-effective roofing solutions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!