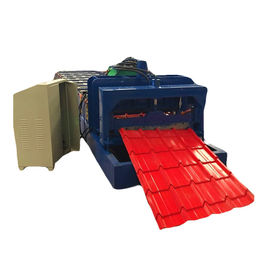

Guide Pillar Steel Color Roof Tile Roll Forming Machine High Precsion Building Material

Working flow

Uncoiling→Sheet Guiding→Roll Forming→Pressing→Measuring Length &Shearing→Sheet to Support Table.

Technical Parameters

| Material thickness (mm) |

0.3~0.9 |

| Material yield stress (Mpa) |

230~300 |

| Max. forming speed (m/min) |

4-6m/min |

| Roller material |

45# steel with chrome treatment |

| Roller driven type |

Chain transmission |

| Controller & operation |

PLC & touch screen and button |

| Hydraulic system pressure (Mpa) |

12 |

| Hydraulic station motor power (Kw) |

5.5 |

| Main motor power (Kw) |

3 |

Machine components list:

| Name |

NO. |

Unit |

| 1.De-coiler |

1 |

set |

| 2.Forming machine |

1 |

set |

| 3.Pressing and Cutting device |

1 |

set |

| 4.PLC control box |

1 |

set |

| 5.Hydraulic pump station |

1 |

set |

| 6.Production support table |

1 |

set |

Detail Information

1. DECOILER

(1) Max. Width: 1500 mm

(2) Inner Diameter: Φ450 – Φ550 mm

(3) Out Diameter: 1500 mm

(4) Max. Loading Capacity: 5000 kgs

2. ROLL FORMING MACHINE

(1) Material Thickness: 0.3-0.8mm PPGI and GI

(2) NO. of roller Stations: 13roller stations

(3) Material for Rollers: high grade 45# steel polished and coated with chrome HRC55-60°

(4) Material for shaft: high grade 45# steel polished and coated with chrome HRC55-60°

(5) Diameter of shaft: 70mm

(6) Frame panel thickness: 20mm

(7) Bottom frame: 36# H-section steel

(8) Motor Power: 3kw

(9)Driven type: 1.0"Chain

3. PRESSING AND CUT-OFF DEVICE

(1)Material for Cut-Off Modular:Cr12 steel after treatment

(2)Hardness for Heat Treatment:HRC55 – 60°

(3)Cut-Off Type:Hydraulic, Automatic Cut-Off

(4) Motor for Hydraulic Stand: 3kW

(5) Press tool material: Cr 12 steel after heat-treated

4.PLC CONTROL BOX

(1) Type: PLC Frequency Control System with touch screen

(2) PLC Brand: Delta

(3) Encoder Brand: Omron

(4)Length Error: ±2mm

(5)Language: English and Chinese

(6)Voltage: 380v/50HZ, 3Phase (it depends on customer requirement)

Terms of Payment

a.Payment type: 30% T/T for advance payment and balance should be paid before delivery.

b.Delivery time: 30 days after received advance payment.

c.Guarantee period: 24 months.

Installation and Training:

a.If buyers visit our factory and inspect the machines, we will teach you how to install and operate the machine, and also train buyer's workers/technicians on live.

b.No visit, we will send you instruction manual and videos to teach you how to install and operate.

c.If buyer needs our technicians to go to their factory, it needs round air ticket, accommodation and etc.

After Service

a.One year guarantee for the whole machine.

b.24 hours technical support by email, Skype, WhatsApp, Wechat or phone call.

c.Suppose some parts were damaged, we would replace for free by express delivery within warranty period.

Customer visited factory

Welcome to visit our factory anytime

1.You can fly to Beijing or Tianjin airport, i can go to pick you.

2.You can fly to Shanghai, then from Shanghai Hongqiao station to Cangzhou XI railway station, i will go go to pick you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!