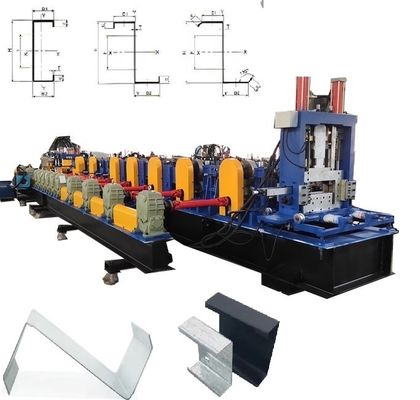

C purline, U purline, M purline Z purline, C & Z purline rolling forming machine

C purline, U purline, M purline Z purline, C & Z purline rolling forming machine

CZ steel can be used for building main structure, and after deep processing, it can well meet the design requirements of building structure, making the building structure more stable and reliable. C-shaped steel is mainly used on some wall beams and sandalwood strips in buildings, which can obtain a relatively sturdy building structure. Z-shaped steel is a common cold-formed steel that is commonly used in large steel structures, especially in buildings like factories, and has seismic resistance. Shelves, vegetable greenhouses, and furniture: CZ steel is also used in the production of shelves, vegetable greenhouses, and furniture.

According to the usage and application of purlines, designed the following types C purline, U purline, M purline Z purline, C & Z purline rolling forming machine;

1. Light duty purline roll forming machine ( Thickness from 1 to 2.5mm for example)

2. Heavy duty purline roll forming machine (Thickness form 1.5 to 3.5 or 4.5mm)

3. Fully automatic CZ purline machine

4. C U Z M purline machine

5. Semi automatic purline rolling forming machine (From C to Z by handrail or by PLC adjustment)

Take the following sizes for example to show you how the Fully automatic CZ purline machine is designed: Take those popular sizes for your reference, all those could be made by one machine

How to choose the proper machine according to your needs?

1. Please choose the machine mode according to the material thickness , hardness. For example, in USA we use SG550 full hard steel and the thickness to 4.5mm and then we have to use the gearbox type heavy duty types. If just the thickness from 1.0 to 2.5mm, and only soft steel and then we can use the light duty CZ purline machine.

2. Choose the CZ purline mode, considering the bottom width. If the bottom width to 400mm or more bigger, better we choose the heavy duty mold.

3. Choose the CZ purline mode, according to the automatic degree: For example if you want to adjust the thickness range automatically, if you want to change the sizes by PLC, if you want to change shape from C to Z and then we can choose the fully automatic mold.

4. If you choose the CZ mold, please consider your budget. If you feel that you have the processional engineer and you can handle the machine easily meanwhile your budget is limited and then we can consider the economic type, using chain as transmission, manual adjustments.

In the following part, I will introduce the automatic type:

At the leveling part, there is also servo motor, once the input coil width changes, the leveling part will do the adjustment automatically.

Feeding flat roller+double pairs of neutral rollers. The feeding guide can move independently at the front and back of the guide rollers, meaning that the rollers can be adjusted left and right separately. The handwheel must be on the operating side and have an overall lateral movement function.

Servo adjustment of waist height and bottom width, thickness adjustment through servo motor centralized drive of worm gear and worm gear adjustment, worm gear and bearing positions have oil injection holes, CZ exchange for manual adjustment.

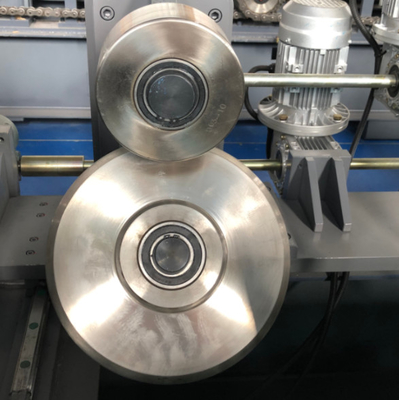

Bearing cover and nut: chrome plated

Forming rows: 16 rows

Roller material: Cr12, heat treated to HRC58-60 after CNC machining, precision turning

Axis material: 40Cr

Shaft diameter: 70/95mm

Transmission mode: gearbox

Speed: approximately 20-40m/min

Main motor: 45 kW * 2 units, Siemens AC variable frequency motor

Gear reducer: K series

Size adjustment motor power: 2 * 1.5kw+2.2kw, Siemens servo motor V90

Adjustment of roller clearance for different thicknesses: 8 * 0.75kw (according to actual design)

Straightening: Ensure the straightness of the finished product

Hydraulic cutting: tracking cutting, 45 degree twisting, no waste, one model with one pair of blades

Cutting mold material: Cr12 mov

Cooling system: Water cooled lubrication system, with water tank and pump. A filter screen is added at the inlet of the water tank to prevent water debris from entering the water tank and damaging the pump

Voltage: 460V, 60Hz, 3ph, (according to customer requirements)

At the top of frame, we will design with the servo motor also, from example the thickness from 1.5 to 3.5mm, we can make it automatic changes according to the PLC control, by this way, we can make it 100% accurate.

When handling super thick or heavy duty type, automatic stacker is necessary also.

On the other hand, let me share some more economic design C & Z purline rolling forming machine for your reference: This type we can use the chain as transmission and then cost will be more lower.

As to the CZ purline machine punching part, we have three types for your reference:

1. Independent punching, which is for more punching.

2. Before punching, if the punching at the side, we have to do the before punching

3. After punching, if the punching at the bottom and near the end, we can use the after punching.

This punching is good if you have lots of holes to punch, by this type we can change dies easily and enhance the machine working speed.

After punching:

What if the solution, I just want to make one fixed size?

You can choose this type middle plate type, cost will be more lower and more easier to use.

For more question, you can contact us at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!