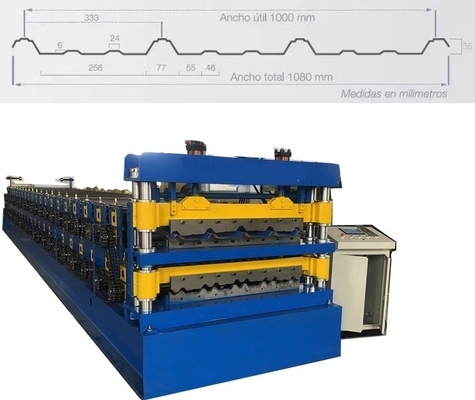

Double layer roofing sheet machine to South America

Double layer roofing sheet machine to South America is a type metal roofing sheet rolling machine we made. The drawing profile is specially for South America Colombia. Same with other metal roofing sheet machine, we promise quality, speed. The following two drawing profile for example and then I will show you more parameters of the metal rolling machines.

Double layer roofing sheet machine pictures:

Packing list-roof profile machine

Máquina de perfil de techo de lista de embalaje |

| No. |

Name |

Unit |

Qty |

Note |

| Part 1 |

5T manual decoiler

Desbobinador manual 5T |

set |

1 |

You can choose hydraulic one instead

Puedes elegir uno hidráulico en su lugar

|

| Part 2 |

Guide feeding device

Dispositivo de guía de alimentación

|

set |

1 |

With hand cutter

Con cortador de mano

|

| Part 3 |

Main roll former

Método de laminado separado del formador de rodillos principal

|

set |

1 |

Chains drive

Accionamiento por cadenas

|

| Part 4 |

PLC control station

estación de control PLC

|

set |

1 |

Delta brand

marca delta

|

| Part 5 |

Cutting system

Sistema de corte

|

set |

1 |

Hydraulic

Hidráulico

|

| Part 6 |

Hydraulic oil pump station

Estación de bombeo de aceite hidráulico

|

set |

1 |

With cooling fan

Con ventilador de refrigeración

|

| Part 7 |

Simple collect table

Mesa de recogida sencilla

|

set |

1 |

You can choose automatic stacker instead

Puede elegir el apilador automático en su lugar

|

| Part 8 |

Spare parts Piezas de repuesto |

set |

1 |

|

Double layer roofing sheet machine to South America Advantage:

1. With handrail for easy adjusting the coil width and supporting rollers.Equipped with 2 plastic bands in the middle of the platform and two pinch plates to feed the material, prevent the material surface from being damaged, and feed the material more easily and quickly. With hand wheels to adjust the feeding size, more conveniently.

2. With the manual cutter for cut the at any stop easily.

3. With rubber rollers to feed the material more smoothly and with the gear outside to make the down and up shaft move at the same time. Upper layer and down layer with two gears on the outside, so that the upper axis of each layer runs passively to actively, with more power and faster.

4. Up layer and down layer with manual cutter to cut feed material more easily.

Advantage of the rollers: For all of our rollers, spacers and shafts, we all mark numbers on it, it’s very convenient for you to maintenance the machine in the future.

There is ball bearings inside the rollers, to make all the rollers run at same speed when machine is run. 3. Because the rollers inside with ball bearings, our rollers is bigger than others, so work speed is faster. 4. All rollers and spacers, we do 3mm thickness chrome coating, to increase hardness and anti-rust. Some factories maybe use 1-2mm chrome coating.

All those designs, we just want to make sure the machine quality can be more better. The machine made by us really could be used as tools to earn money back.

There are more advantages we can not list them all here. If you want to know all, please contact me at any time. If you need the protection cover, we can also make for you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!