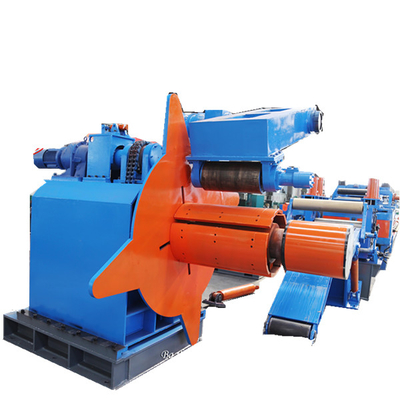

HG127 Straight seam square pipe round tube roll forming machine

HG127 Straight seam square pipe round tube roll forming machine is designed to make the tube by rolling forming principle and welding rules. It is used for round pipe welding and also for square pipe welding. It is suitable for low-carbon steel and low-alloy steel. The material is galvanized aluminum-magnesium. The cooling water for water, electricity, gas and mechanical parts is sent to the corresponding interface of the equipment by the buyer. All accessories (including pumps, pipelines, cables, air compressors, etc.) within the interface are completed by the supplier.

(1) Raw materials:

1. Strip steel material, yield strength 295MPa

2. Strip width: 235-390mm

3. Strip thickness: 1.5-4mm

4. Strip steel coil: inner diameter Φ610-Φ760mm, outer diameter Φ1100-Φ1800mm, coil weight ≤8 tons

(2) Unit requirements:

1. Working direction of the unit: Left feed

2. Unit color: the base is gray, and the base above is blue

3. The production speed of the unit: 30-50m/min

4. Total power consumption: about 180KW, bidders can fill in according to their actual situation.

HG127 Straight seam square pipe round tube roll forming machine

Process flow of pipe production line:

Coiling (trolley)—Uncoiling—Straight Head—Pinch Leveling—Shearing Butt Welding—Horizontal Spiral Looper—Forming Machine—High Frequency Welding—Scratching—Scratch Repairing Zinc Magnesium Aluminum—Cooling—Sizing Machine—Turkish Head —Flying saw—Runway—Automatic palletizing—Packing—Warehousing

There are lots of elements are elements are optional:

First, decoiler you can choose the automatic type or the manual one.

Second the leveling and welding part, you can choose automatic type or the manual one.

Third as to the shearing part and welding part, it is also optional.

Forth: as to the accumulator, it is also optional cage type or the spiral type.

Fifth; for making sure the quality of rolling machine,there is no option. It is fixed.

Material of horizontal rack and distribution box: ZG35

Straightening the turkey head: 2 racks (four-roller type)

Straightening the Turkish head shaft: Φ70 (bearing 22316)

Straightening Turkish head shaft material: 40Cr

Straightening head adjustment method: worm gear

So when compared the price, please tell me the more detail requirement and then we can quote you more accurately.

For the tube line, we have HG14, HG32, HG50, HG76 and others types according to the different thickness and pipe diameter.

When you need the details specification, please give us the following information and then we can make the accurate quotation for you:

1. What is the material and how about the thickness.

2. How many sizes you want to make?

3. What kind of speed is better for you?

If you need to know more information, please contact us at any time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!