LED light box profile rolling forming machine (T5 profile rolling machine)

LED light box profile rolling forming machine is designed to make the metal profiles for LED light in batch fully automatically. Before the LED light box profile uses the Cast aluminum or plastic but for lower down the cost those days, some customers choose to use the metal profile by rolling forming machine. By this way, the profile material could be either aluminum or metal or others. Here we take some drawing profiles for your reference:

PROFILE A:

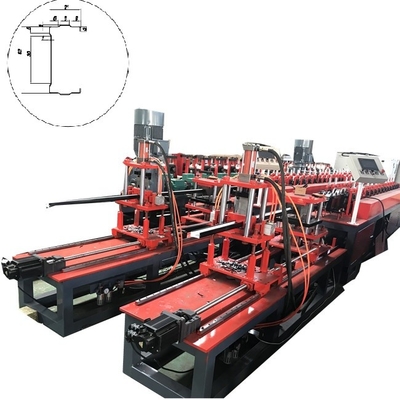

LED light box profile rolling forming machine pictures:

The LED light box profile rolling forming machine is composed by the following elements: Decoiler with the leveling machine, punching holes system, main rolling forming machine with hydraulic shearing system and receiving table.

It supports the following material:

Product material thickness: 0.3 mm

Product material width: () mm the final plate width shall be determined according to the commissioning results

Product forming speed: 2~8 m/min

Product length error : ± 1mm/3m

Total power of equipment: 13kw

Power consumption of equipment: AC 380V, 50Hz, three-phase

Control power: AC 220V, 50Hz, single phase or customize.

Main rolling forming machine each element parameters:

Servo feeder

Feeding thickness 0.3-1.5mm

Feeding motor 1.5kw

Feeding accuracy +-0.1mm

Hydraulic punching machine

Stamping tonnage 10t * 2 punches

Punching die Cr12MoV

Molding machine, the frame adopts integral structure square tube welding (80x80)

Side plate 25mm Q235

The feeding type adopts guide plate to guide the material

Number of forming rolling wheel groups 22 groups +6 wheel straightening mechanism

Forming roller material Cr12, processing and quenching of rolling wheel, hardness hrc58-60 ℃

Spindle Φ 38mm quenching and tempering treatment

Main shaft bearing (each side plate) 6206

The main engine is powered by a 4kw motor with variable frequency speed regulation and equipped with a 4# cycloid reducer. The transmission system of the main machine is driven by the motor, which is connected with the linkage gear through the cycloid pin reducer sprocket to drive the binding wheel to rotate synchronously

Hydraulic motor power 2.2kw

Cut off mode shutdown, hydraulic cut-off. Blade thickness 3mm

Some holes could be punched before rolling forming, some need to be made after rolling forming.

Electronic control

Total power of equipment: 13kw

Power consumption of equipment: AC 380V, 50Hz, three-phase

Inverter inverton

Other components Schneider

PLC Panasonic Japan

Touch screen Taiwan vinylon

Here are more types for your reference:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!